How we work

Starting from Zero, with Pure enthusiasm and sincerity. That’s how we began and that’s how we still work today. In every new project, we always start with a ‘phase Zero’ – a phase of listening to the client to optimise ideas and creativity. Then, without preconceptions or technical restraints, we apply Pure enthusiasm to putting ideas into practice. In this way, we always find the best way to turn our clients’ concepts into finished products.

Techniques and services

All phases in the development of a new product are completed in-house, from conception right through to industrialisation. This allows us to guarantee the highest level of accuracy and customisation in the finished product, along with authentic Italian quality.

The production process

Conception and design

Our technical department is staffed by a team of 6 experts who support clients and stylists in the graphic and technical design phases in order to fully understand their vision and transform it into a functional and innovative new product.

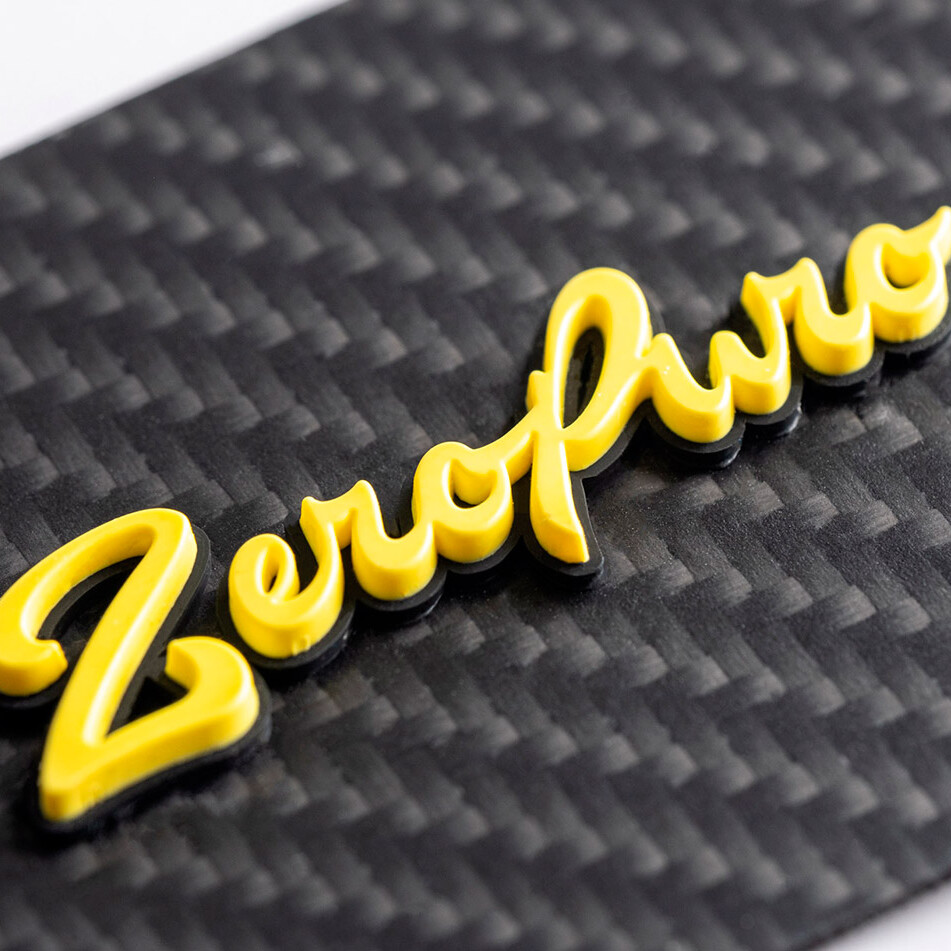

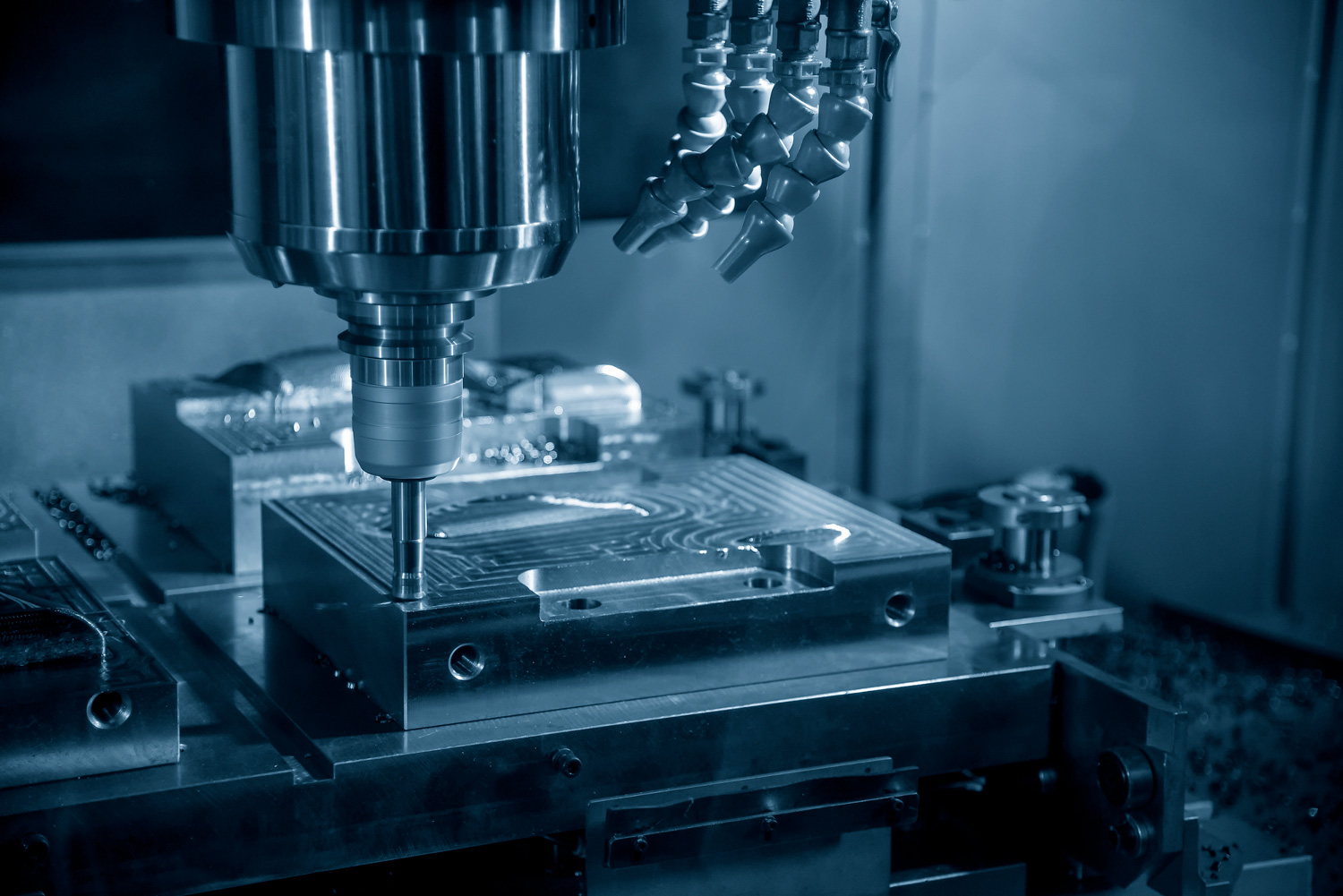

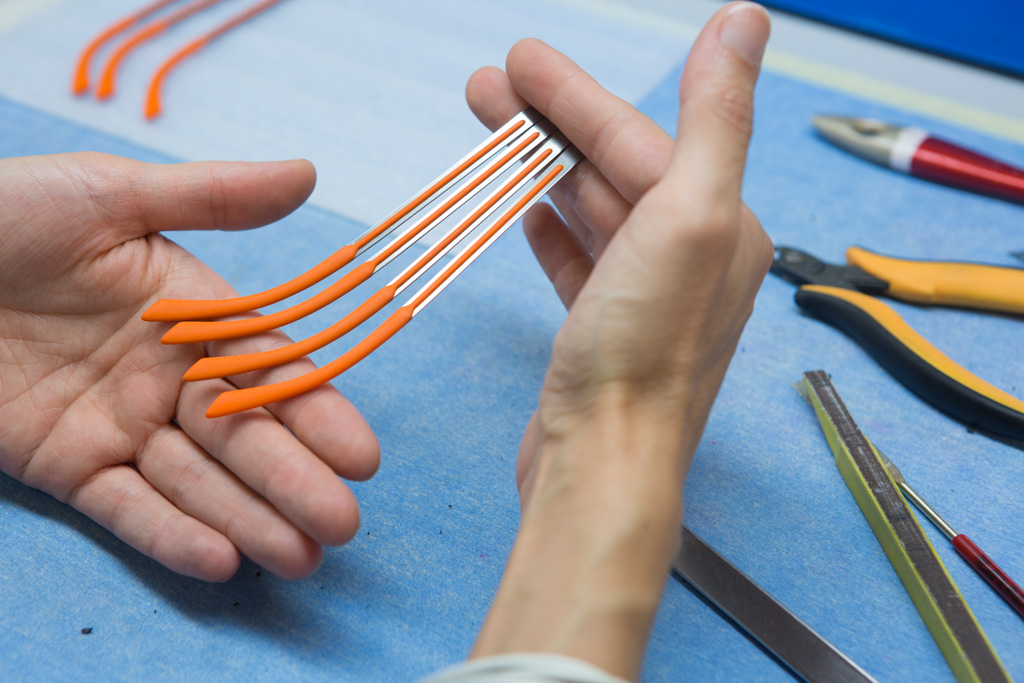

Mould and prototype development

We are fully autonomous in the design and production of all the moulds needed for production. We own 5 CNC milling machines, 3 laser engravers and a specially equipped workshop for the accurate and rapid finishing and production of moulds.

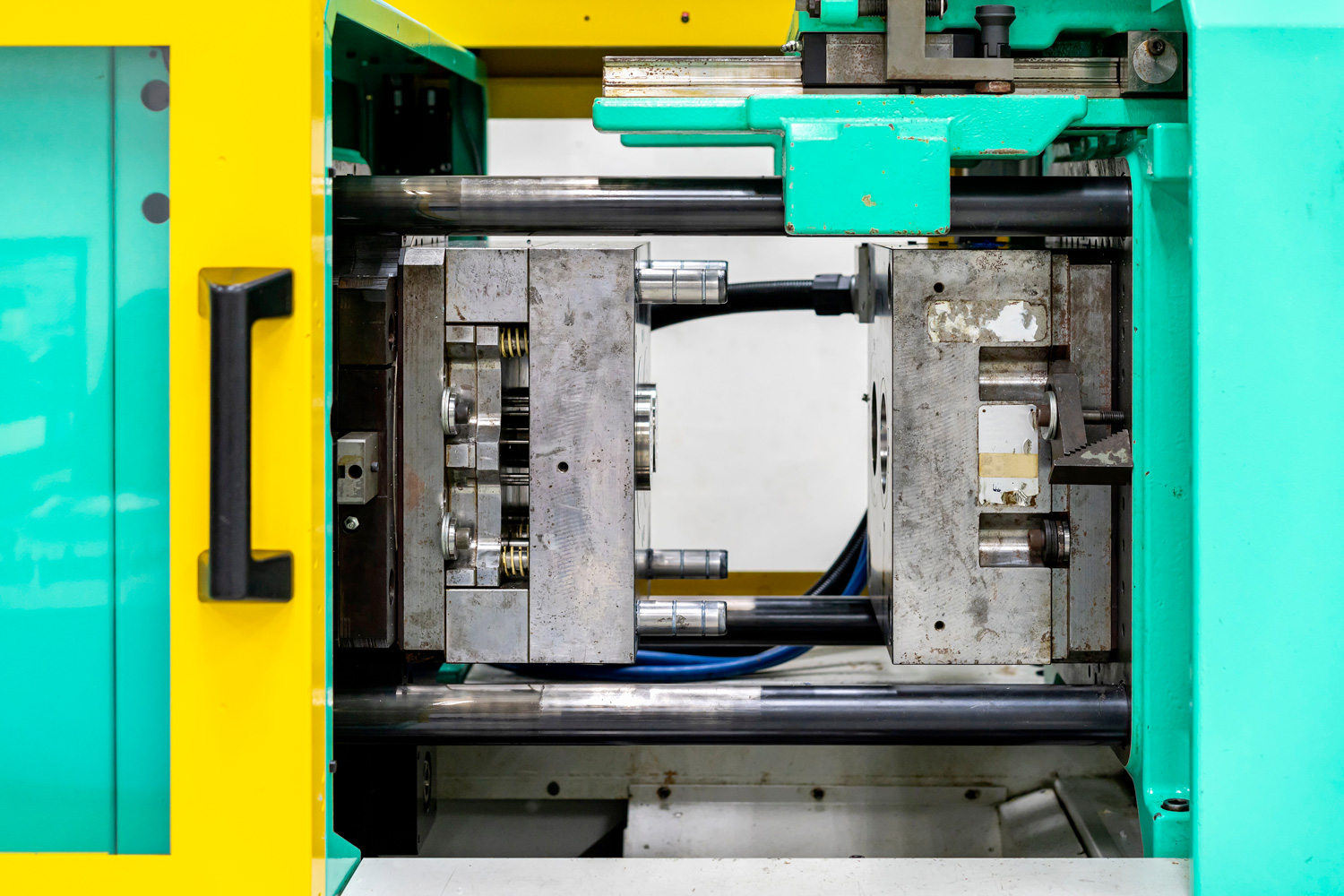

Industrialisation and production

At the end of the prototyping phase, we establish how best to industrialise the product. Our plastics moulding department is equipped with 27 injection moulding machines of different tonnage, both horizontal and vertical, as well as a new robotic micro moulding system for liquid PVC. Our milling department operates 6 multi-tool mills for cutting and engraving carbon fibre and wood.

Quality control

At the end of production, quality checks are essential to ensure that every article satisfies the necessary standards. We subject every lot we produce to rigorous quality control, checking for the absence of defects and ensuring conformity to the relevant technical specifications. Correct colours are achieved using specific colour formulae to guarantee a uniform finish.

Do you want to start a new project? Contact us!

We develop innovative solutions that allow designers

and stylists to express their creativity to the full!